Jaw Crusher for Sale Quality: Uncovering Quality Options

Jaw Crusher for Sale Quality: Uncovering Quality Options

Blog Article

Obtain the A Lot Of Out of Reusing With a Versatile Jaw Crusher

And when it comes to making the most of the advantages of recycling, a functional jaw crusher shows to be an invaluable tool. Well, in this conversation, we will discover the types of products that can be refined, the advantages of making use of a jaw crusher for recycling, and the essential attributes to look for. We will likewise dive into the actions to optimize the recycling procedure and display some successful situation researches.

Sorts Of Products That Can Be Refined

Various sorts of materials can be successfully refined utilizing a jaw crusher. Among the key advantages of a jaw crusher is its capability to take care of a vast array of feed sizes and products - jaw crusher for sale. From construction and demolition waste to concrete and asphalt, a jaw crusher can efficiently refine numerous products and turn them into recyclable accumulations

For example, in construction sites, a jaw crusher can process products such as concrete, bricks, and stones. These materials can be crushed right into smaller sized dimensions and made use of as a base for brand-new construction tasks. In mining procedures, a jaw crusher can manage numerous kinds of ores, consisting of gold, copper, iron, and silver. The jaw crusher's durable style enables it to manage durable applications and procedure big quantities of ore effectively.

Furthermore, a jaw crusher can also refine products such as granite, gravel, and sedimentary rock. These materials are typically used in the manufacturing of concrete, asphalt, and various other building materials. By squashing and recycling these materials, a jaw crusher adds to sustainable techniques in the building and construction market and decreases the demand for drawing out and processing natural deposits.

Advantages of Making Use Of a Jaw Crusher for Recycling

A jaw crusher uses various benefits for recycling applications due to its convenience and effectiveness in refining a wide variety of products. One of the vital benefits of a jaw crusher is its capacity to process tough and abrasive products. This makes it optimal for recycling applications, as it can manage materials such as concrete, asphalt, and demolition waste effortlessly. Additionally, the adjustable jaw setup and hydraulic toggle system enable specific control over the size of the end product, making it feasible to generate recycled materials that fulfill particular needs.

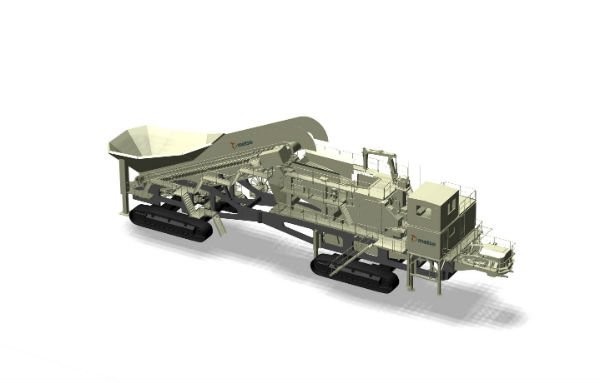

Another advantage of making use of a jaw crusher for recycling is its compact dimension and ability to move. Jaw crushers are generally smaller sized and extra mobile than other types of crushers, making them simple to relocate and move around recycling sites. When functioning in cramped or restricted locations., this is specifically beneficial.

Additionally, jaw crushers are extremely effective makers that can refine huge quantities of product quickly. They have a high throughput capacity, implying they can deal with big volumes of recycled material in a short amount of time. This makes them optimal for high-volume recycling operations.

Secret Attributes to Look for in a Versatile Jaw Crusher

When picking a versatile jaw crusher, it is vital to consider essential attributes that enhance its functionality and efficiency. In addition, a versatile jaw crusher ought to have a high squashing ability, allowing it to deal with a large array of products and processing demands. Generally, picking a versatile jaw crusher with these key functions will certainly make it possible for reusing procedures to achieve optimal performance and take full advantage of the advantages of recycling.

Steps to Optimize the Recycling Process With a Jaw Crusher

To maximize the reusing procedure with a jaw crusher, it is important to execute efficient steps that enhance the general functionality and productivity of the crusher. The primary step is to ensure appropriate maintenance and routine examinations of the jaw crusher. This includes checking for any wear or damages to the components, along with oiling the bearings and various other relocating elements. jaw crusher for sale. By keeping the crusher in great condition, it will be able to operate at its maximum ability and supply regular results.

Another important action is to correctly size the feed material. This includes understanding the requirements of the reusing procedure and selecting the appropriate jaw crusher dimension and setup. By utilizing the appropriate dimension crusher, the material can be refined extra effectively, leading to enhanced productivity and lowered downtime.

Additionally, it is crucial to have a properly designed feeding system in location. This includes using a shaking feeder or a grizzly feeder to regulate the circulation of material right into the crusher. By managing the feed price, the crusher can operate at optimum levels and protect against overloading.

Additionally, it is very important to change the crusher setups according to the desired outcome size. This can be done by changing the CSS (shut side setting) and the stroke of the crusher. By maximizing these settings, the crusher can create the desired product dimension and reduce the quantity of recirculating product.

Study: Effective Reusing Projects Utilizing a Jaw Crusher

Numerous successful recycling jobs have actually utilized a jaw crusher to accomplish their objectives. These study offer as instances of exactly how a jaw crusher can play an essential function in the reusing industry.

One such project included the recycling of concrete waste. The jaw crusher was made use of to crush the concrete into smaller items, which were after that made use of as a base material for road construction. By recycling the concrete waste, the job not just reduced the amount of waste sent to garbage dumps yet additionally saved money on the cost of buying brand-new products.

Another instance study focused on the recycling of asphalt. The jaw crusher was used to damage down the asphalt right into smaller sized pieces, which were then used to create brand-new asphalt sidewalk. This not only minimized the expense of buying new asphalt but additionally lowered the requirement for basic materials and energy intake linked with asphalt manufacturing.

In yet one more project, a jaw crusher was made use of to reuse metal waste. The crusher was able to crush and separate the metal waste into different portions, enabling much more efficient recycling. This not just minimized the amount of steel waste sent to landfills yet likewise saved on find more information the price of buying new steel materials.

Final Thought

In go to this web-site final thought, a versatile jaw crusher supplies various advantages for reusing functions. It can efficiently process a large range of materials, causing effective recycling procedures. Key attributes to take into consideration include the capacity to manage different kinds of materials and the crusher's durability. By maximizing the recycling procedure, successful tasks have shown the efficiency of using a jaw crusher in reusing operations.

Well, in this discussion, we will explore the types of products that can be processed, the advantages of making use of a jaw crusher for recycling, and the crucial features to look for. By crushing and reusing these materials, a jaw crusher contributes to lasting techniques in the building sector and reduces the requirement for removing and processing natural sources.

A jaw crusher offers various benefits for reusing applications due to its versatility and effectiveness in refining a wide range of materials. Jaw crushers are commonly smaller and more mobile than various other kinds of crushers, making them very easy read this to relocate and move around recycling sites.To optimize the recycling procedure with a jaw crusher, it is crucial to implement effective steps that improve the general capability and productivity of the crusher.

Report this page